In the fast-paced world of automotive manufacturing, car bumper mould makers are playing a crucial role in shaping the future of automotive design. These skilled professionals are responsible for creating the molds that shape the exterior of cars, specifically the bumpers, ensuring precision, quality, and innovation in the production process.

Car bumpers are an integral part of any vehicle, providing both aesthetic appeal and crucial protection. As automotive design continues to evolve, car manufacturers seek to create bumpers that are not only visually appealing but also lightweight, aerodynamic, and capable of absorbing impact during collisions. This is where the expertise of car bumper mould makers comes into play.

The process of making car bumper molds involves a combination of cutting-edge technology, engineering prowess, and attention to detail. The first step is to analyze the design specifications provided by the car manufacturer. Mould makers use computer-aided design (CAD) software to transform the 2D designs into 3D models, allowing for precise measurements and intricate detailing.

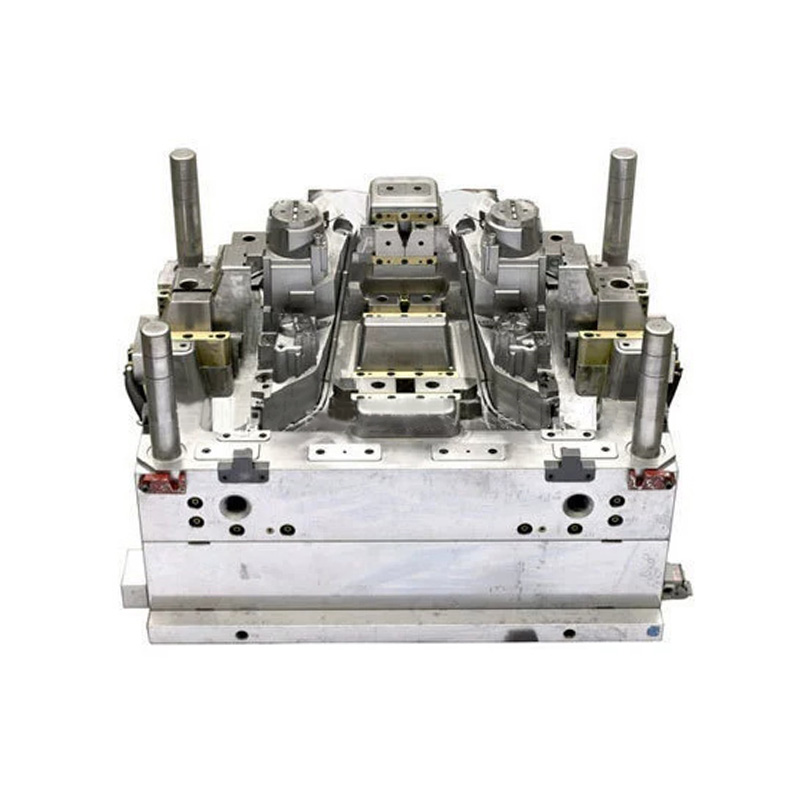

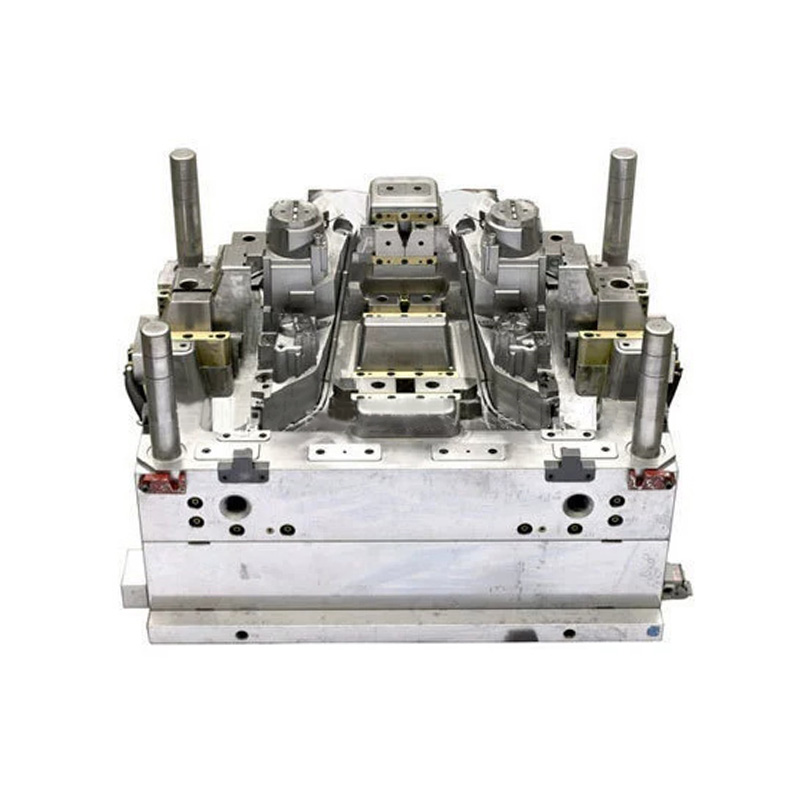

Once the 3D model is finalized, car bumper mould makers utilize computer numerical control (CNC) machining techniques to carve out the mold from a solid block of material, typically steel or aluminum. This process requires high levels of precision and accuracy, as any flaws or imperfections in the mold can result in defects in the final bumper product.

The expertise of car bumper mould makers extends beyond simply creating the mold. They are also responsible for selecting the appropriate materials for the mold based on factors such as durability, temperature resistance, and ease of maintenance. The choice of materials plays a crucial role in ensuring that the molds can withstand the rigors of the manufacturing process and produce bumpers that meet the desired specifications.

In addition to their technical skills, car bumper mould makers are constantly innovating and keeping up with the latest advancements in automotive design. They work closely with car manufacturers and designers to explore new materials, manufacturing techniques, and aesthetic trends. By staying at the forefront of automotive innovation, these professionals contribute to the development of bumpers that not only enhance the overall look of the vehicle but also improve safety and performance.

The role of car bumper mould makers in the automotive industry is becoming increasingly important as the demand for customized and environmentally friendly vehicles continues to rise. With the shift towards electric and autonomous vehicles, car manufacturers are seeking innovative bumper designs that accommodate the unique features and requirements of these vehicles. Car bumper mould makers are at the forefront of this evolution, working on molds that incorporate lightweight materials, advanced sensors, and streamlined designs to meet the changing needs of the industry.

In conclusion, car bumper mould makers are instrumental in shaping the future of automotive design. Their expertise, precision, and innovation are essential in creating molds that produce bumpers that are not only visually appealing but also lightweight, aerodynamic, and safe. As the automotive industry continues to evolve, car bumper mould makers will continue to play a crucial role in pushing the boundaries of design and manufacturing, ensuring that vehicles are not only aesthetically pleasing but also meet the highest standards of performance, safety, and sustainability.

English

English

中文简体

中文简体

Español

Español