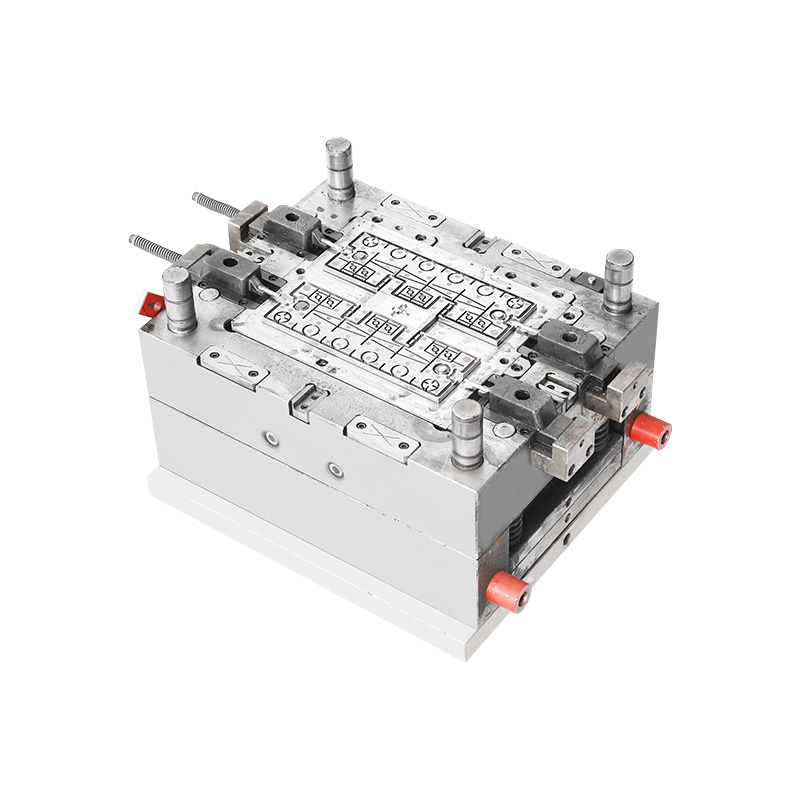

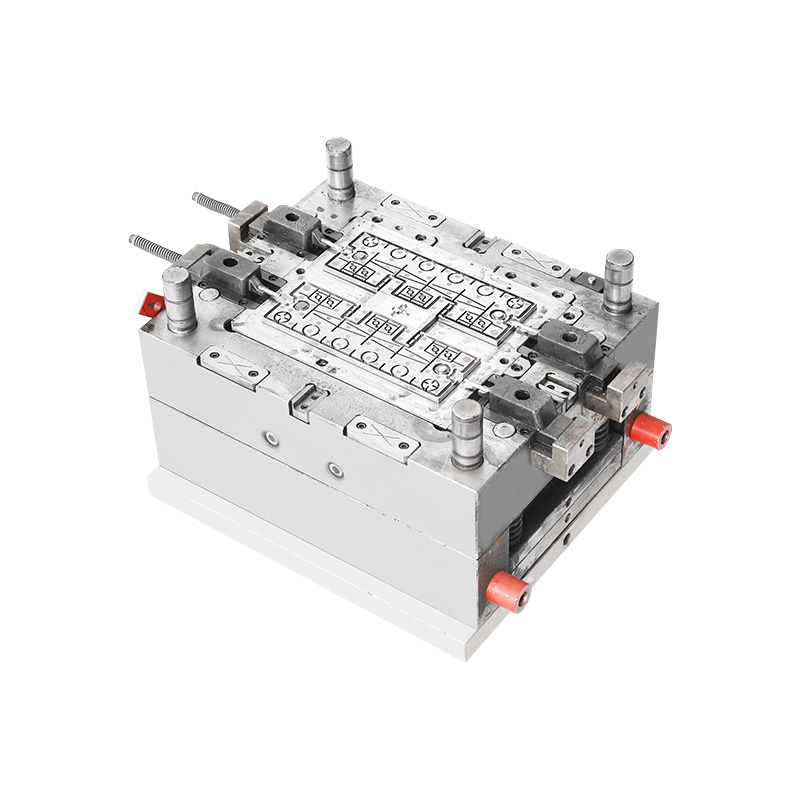

A plastic battery container mold is a tool that is used in the manufacturing process of plastic battery containers. These molds are designed to create a precise shape and size of the battery container, ensuring consistency and quality in the final product. The use of plastic battery containers has become increasingly popular in recent years, as they offer several advantages over traditional metal containers.

One of the primary advantages of plastic battery containers is that they are lighter than metal containers, making them easier to transport and handle. This is particularly important in industries such as the automotive industry, where weight is a critical factor in fuel efficiency and overall performance. Plastic battery containers also offer better resistance to corrosion and are less likely to suffer from leaking, which can be a significant issue with metal containers.

The use of a plastic battery container mold ensures that the manufacturing process is efficient and accurate. The mold is designed to create a specific shape and size of the container, ensuring that all the containers produced are consistent in their dimensions. This is important as consistency is essential for the performance of the battery. A plastic battery container mold is also designed to be durable and long-lasting, ensuring that it can be used repeatedly without any degradation in quality.

When choosing a plastic battery container mold, it is important to consider several factors. The mold must be designed to produce the exact size and shape of the battery container required. The material used to make the mold should be of high quality to ensure durability and longevity. It is also essential to consider the number of cavities in the mold. A mold with more cavities can produce more containers at a time, increasing the efficiency of the manufacturing process.

The manufacturing process of plastic battery containers typically involves several stages, including material selection, mold design and fabrication, injection molding, and finishing. The plastic battery container mold plays a critical role in this process, ensuring that the container is produced to the required specifications. Once the mold is designed and fabricated, it is used in the injection molding process to produce the plastic battery containers. The mold is then removed from the injection molding machine, and the containers are finished and prepared for use.

In conclusion, a plastic battery container mold is a critical tool in the manufacturing process of plastic battery containers. It ensures consistency and quality in the final product, while also improving the efficiency of the manufacturing process. The use of plastic battery containers has become increasingly popular in recent years due to their lightweight, corrosion-resistant, and leak-proof properties. With the right plastic battery container mold, manufacturers can produce high-quality battery containers that meet the demands of a range of industries.

English

English

中文简体

中文简体

Español

Español